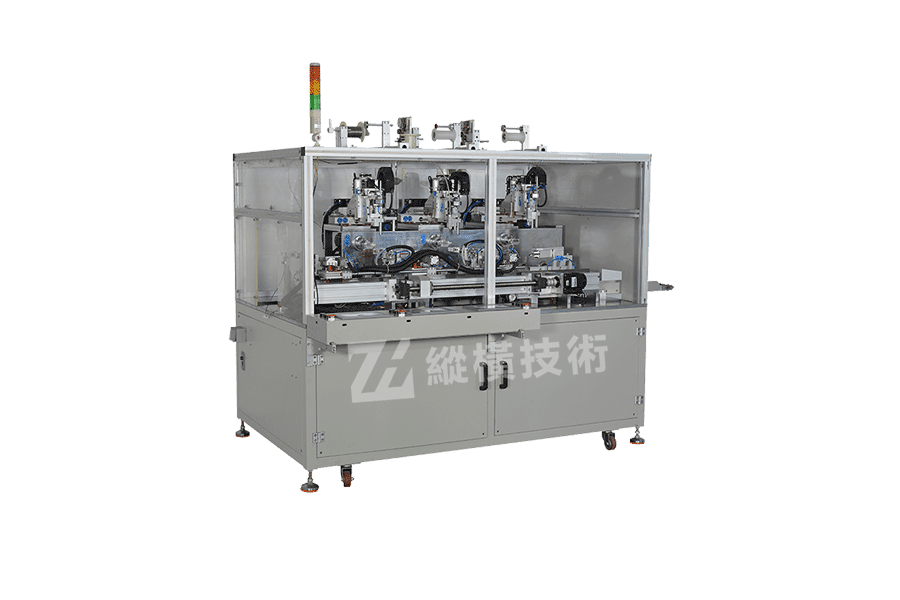

Automobile Magnet Automatic Assembly Machine

Process Flow Of Automobile Magnet Automatic Assembly Machine:

Automatic installation of sliding rod, straightness detection of ejector rod, installation of ejector rod, riveting and pressing of ejector rod, rotary riveting of ejector rod, installation of cushion sheet and spring.

1. The raw material is automatically fed by vibrating plate, no need manpower.

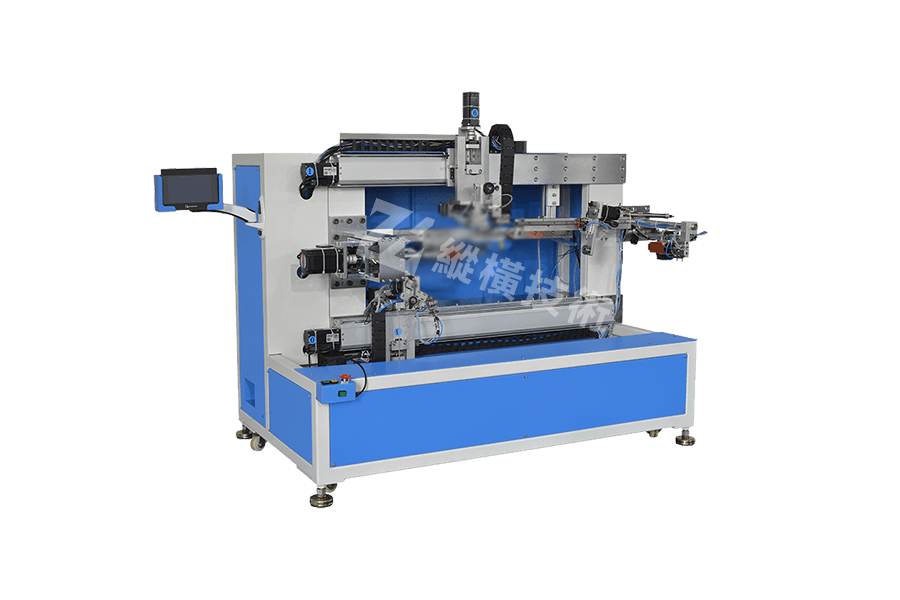

2. The spindle and each dimension are driven by CNC AC servo motors, and the running speed and positioning speed of each axis are fast and accurate.

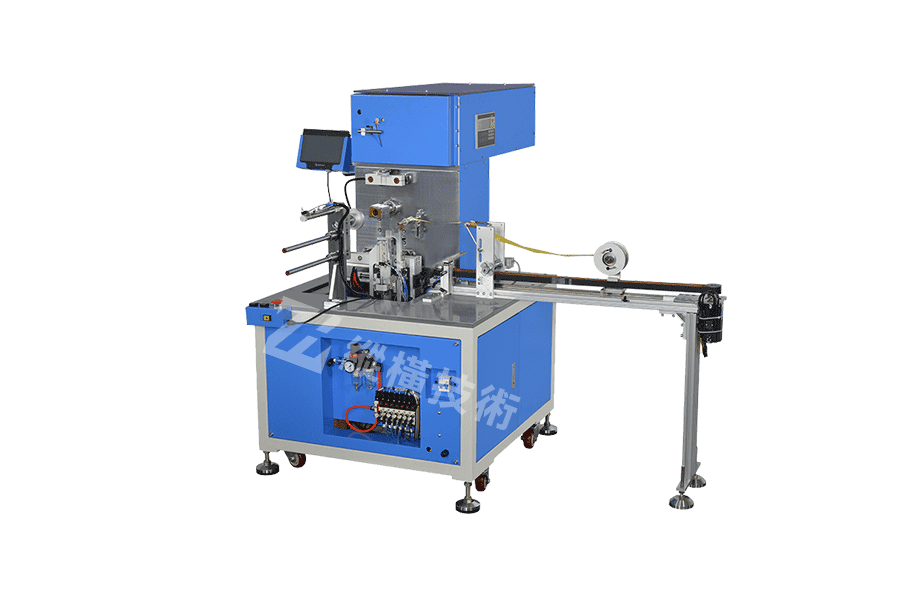

a. Terminal winding can be realized.

b. Programming mode: LCD touch screen programming, providing man-machine interactive visual education system to achieve WYSIWYG (What You See Is What You Get) programming effect.

c. Quick change axial fixture.

3. High speed and high precision, improve winding quality.

4. The wire nozzle guide rod is made of die steel ensure reliable accuracy.

Verticality < 0.01mm/500mm

Parallelism < 0.01mm/500mm

5. Main spindle, XYZ movements are controlled by AC servo motors, and the running speed and positioning speed of each axis are fast and accurate.

6. There are start, emergency stop switches at control area, simple and easy operation, humanized, safe and reliable.