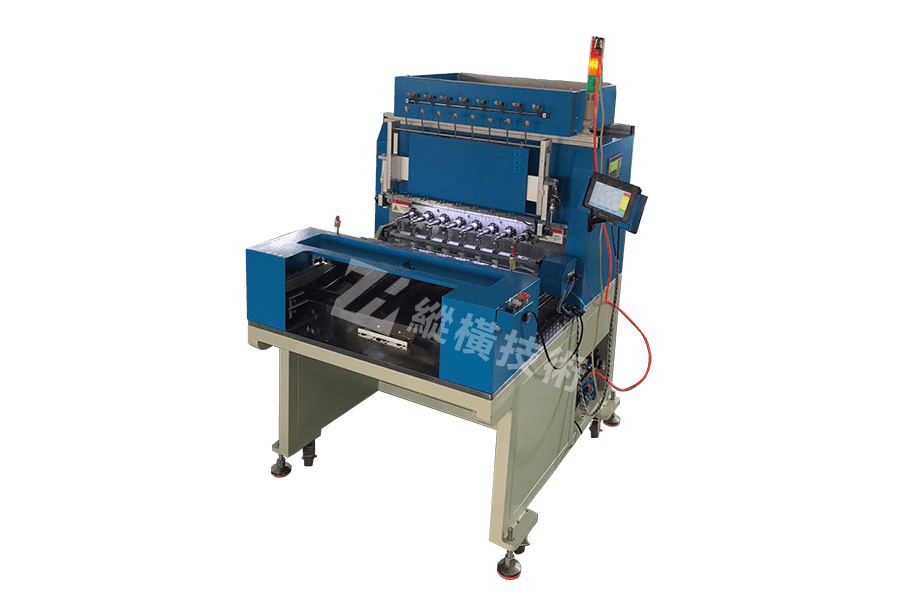

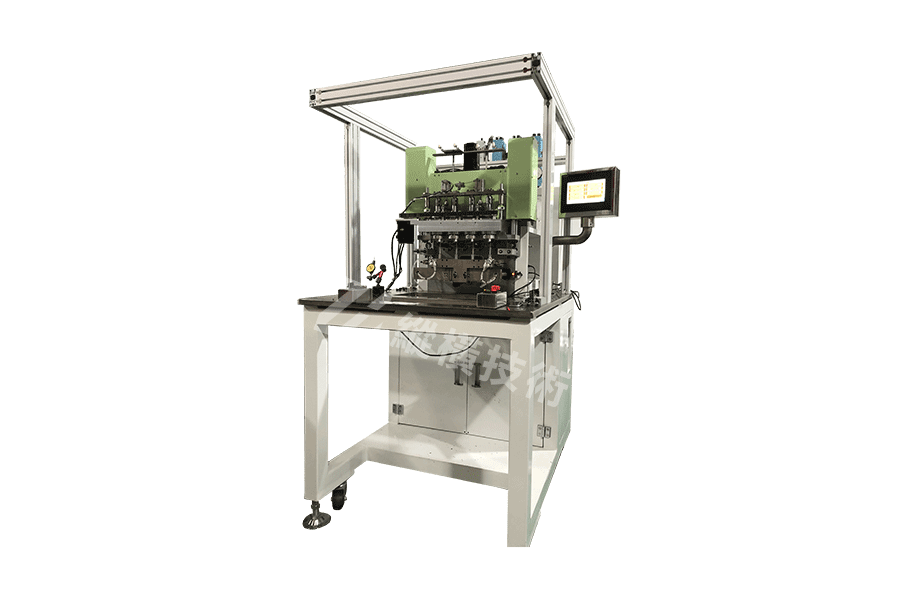

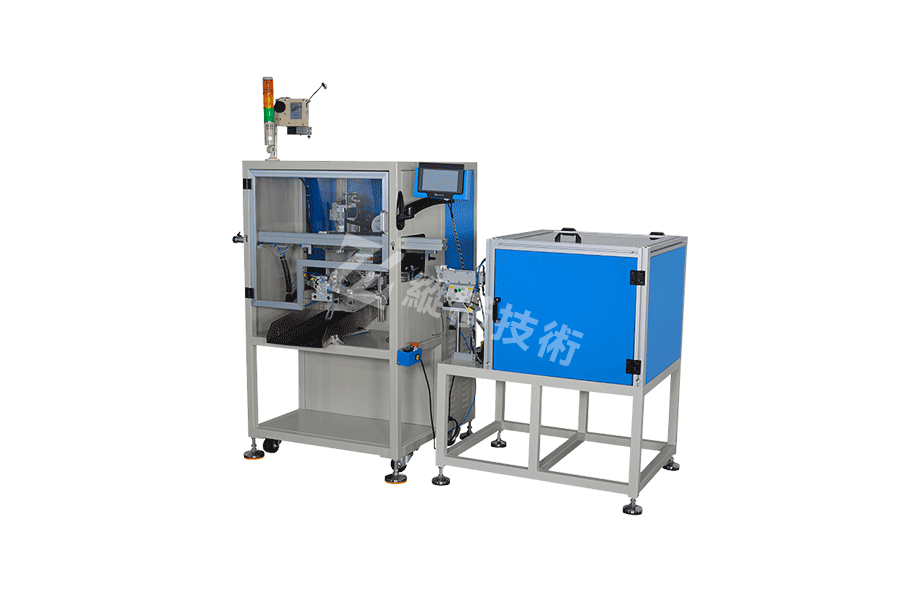

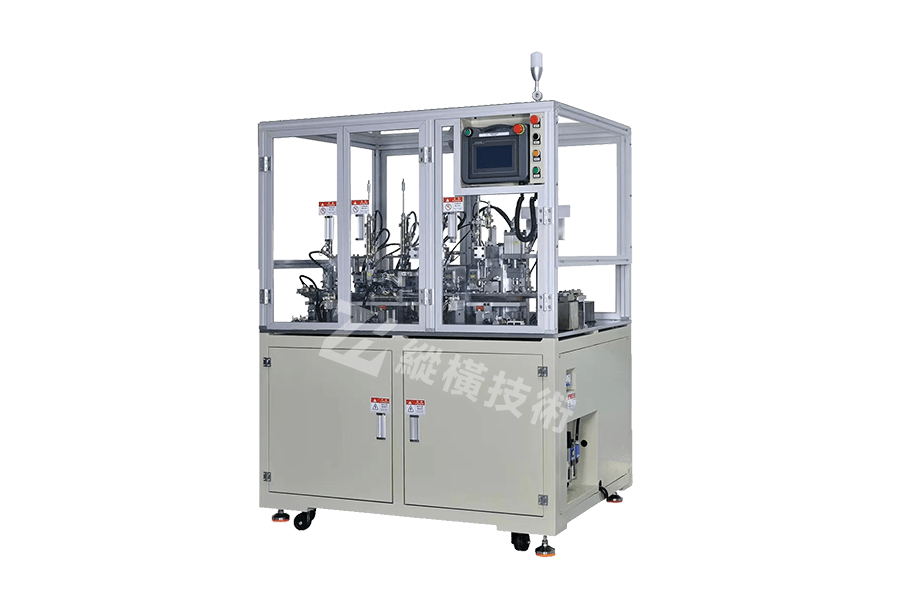

8 Spindles Automatic Precision Winding Machine (Optional 4, 6 spindles)

Product Features:

1. The independent 8-spindle closed-loop automatic monitoring and wire arrangement control system simulates manual wire arrangement. The automatic wire winding system forms a fine-tuning production process through the real-time monitoring device and the wire arrangement and winding system, which can correct the error value accumulated between the wire arranger and the actual multiple turns and multiple layers winding at any time, so as to complete the tight whole row coil winding, such as the whole row close winding of solenoid valve coil, and remove the inefficient and unstable factors that this kind of coil depends on manual wire arrangement. It can automatically complete all kinds of tight and neat coil winding.

2. Programming mode: touch screen programming, providing man-machine interactive visual education system to achieve What You See Is What You Get (WYSIWYG) programming effect.

3. The base adopts seamless welding of steel plate, with large load-bearing, noise reduction and vibration reduction, so as to increase the stability of the machine.

4. Taiwan TBI rail and lead screw are used to ensure the accuracy of positioning and repeated positioning of the machine.

5. Every step of high speed spindle assembly is subject to strict quality control, low noise and long service life.

6. The machine is optional for 4-spindle, 6-spindle or 8-spindle, realizing the best cost performance of the equipment.

7. Automatic winding wire head and tail, automatic winding wire, automatic wire arrangement, automatic clipping, automatic stripping and automatic tape wrapping.

8. Main shaft and XYZ shafts adopt AC servo motors. Ensure fast and precise running speed and positioning speed of each axis.